|

|

|

|

|

|

| GTEM Test Cells |

GTEM Italia |

|

|

GTEM Test Cells for EMC Testing | |

|

DC - 20 GHz

|

The GTEM cell is a TEM waveguide with the upper frequency limit extended to the GHz range. It is a low-cost alternative measurement facility for both radiated emission and immunity measurements. It is included in the published standard IEC 61000-4-20 "Emission and Immunity Testing in Transverse Electromagnetic (TEM) Waveguides". Compared to other measuring methods like EMC test in anechoic chambers or OATS (Open Area Test Sites), GTEM Cells offer some significant advantages for the testing of small and medium sized EUT's (Equipment Under Test) up to a frequency range of 20GHz. Quick turnarounds of the EUT as well as numerous testing variations are easy and fast to handle. Switching from emission to immunity testing requires only simple adjustments, from receiver input to amplifier output.

You are irrespective of long waiting times associated with off-site test labs or weather and ambient delays that can occur at OATS facilities. Whether you are at the design qualification, pre-compliance, compliance, or production sampling stage, the GTEM is the right choice for you. |

|

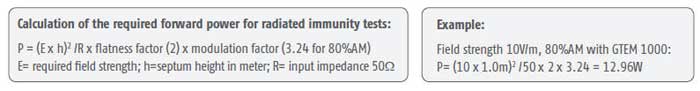

Power Requirements for Radiated

Immunity Testing XYZ EUT Manipulator for GTEM750 & Larger Advantages Over the Competitors GTEM |

|

|

|

GTEM Test Cells acc. to IEC/EN 61000-4-20 |

GTEM Test Cell Optional Accessories |

|

|

|

Copyright © 2001- R. A. Mayes Company, Inc. An Electro Mechanical Research and Development (EMRAD) Corporation, Company See our Privacy Policy All the data files on our website require Adobe Acrobat Reader! |